Active

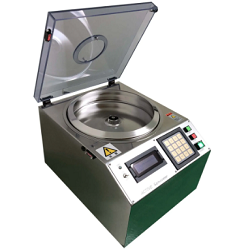

ACT-300AⅡ SPIN COATER

A spin coater (spin coating machine) is a spin coating device that creates a thin film using centrifugal force generated by placing a coating liquid on the top surface of a flat object to be coated and then rotating it at high speed.

Features

Purpose

Main destination

Specifications

| Substrate size | Φ5 to Φ150mm (Max. Φ6 inches, □110mm) Substrate support | ||

|---|---|---|---|

| Weight of workpiece (substrate) | Less than 300g | ||

| Cup inner diameter | Φ300mm | ||

| Outer dimensions | W350×D450×H Door closed 325(Door open 640)mm | ||

| Power supply | 1Φ 100V-10A (AC servo motor 200W) 50 / 60Hz | ||

| Rotation control speed / Rotation accuracy | 0 to 6000rpm / ±1rpm or less (under load) | ||

| Substrate suction pressure | -70 to -80kPa | Vacuum pump displacement 12L/min min. or more.(Outer diameter Φ6 tube one-touch connection on the equipment side) | |

| Number of program steps/patterns | 10 steps/100 patterns (program memory function standard) | Changeable to 20 steps and 50 patterns (Specify at the time of order) | Changeable to 50 steps and 20 patterns (Specify at the time of order) |

| Display screen | LCD display (20 characters and 4 lines) Recipe No., rotation speed, time, adsorption pressure display | ||

| Control method | Microcomputer control (easy programming with numeric keypad input) | ||

| Main unit outer cover/cup material | SUS304 Electropolished (Teflon coating available as an option) | ||

| Safety measures | Safety cover with interlock sensor (automatic rotation stops when cover is opened during rotation) | Interlock function for substrate suction pressure (No rotation when not suctioned) | |

| Weight | Approx. 22kg | ||

| Standard delivery date after receiving an order | Approx. 25 days (please confirm each time) |